Precision is a cornerstone in the manufacturing of Plastic Industrial Tray Mould, as these molds are the foundation for producing trays that meet specific size requirements. The dimensional accuracy of a Plastic Industrial Tray Mould is crucial for ensuring that the final product fits the intended application perfectly. This article delves into the various methods and strategies employed to control the size and shape of Plastic Industrial Tray Moulds with utmost precision.

The process of creating a Plastic Industrial Tray Mould begins with the design phase, where the exact dimensions are specified. Utilizing Computer-Aided Design (CAD) software allows engineers to create detailed blueprints that can be shared with manufacturing teams. These digital models are essential for maintaining consistency and accuracy throughout the production process.

Once the design is finalized, the next step involves the selection of the appropriate materials for the Plastic Industrial Tray Mould. High-quality steel is often chosen due to its durability and ability to withstand the pressures and temperatures involved in the molding process. The material selection plays a significant role in maintaining the dimensional stability of the mold over time.

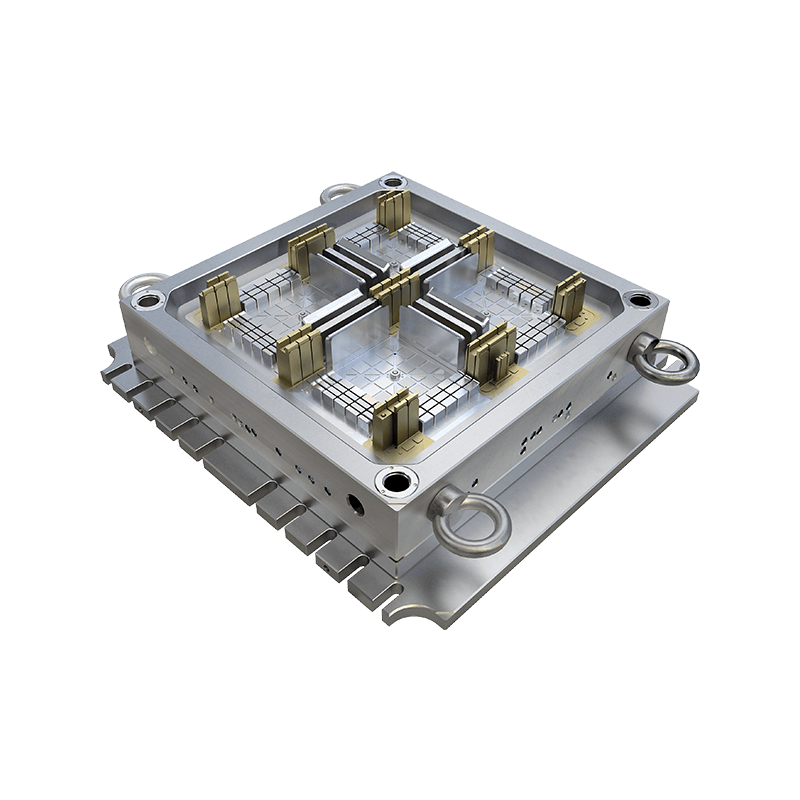

The manufacturing process itself is where the control of dimensions becomes most critical. Advanced machining techniques, such as Computer Numerical Control (CNC) milling and turning, are employed to shape the mold with high precision. These machines can achieve tolerances within a few microns, ensuring that the Plastic Industrial Tray Mould is as close to the design specifications as possible.

In addition to the machining process, the use of Coordinate Measuring Machines (CMM) is essential for quality control. These machines can accurately measure the dimensions of the Plastic Industrial Tray Mould, providing feedback that can be used to adjust the manufacturing process if necessary. Regular inspections using CMMs help to identify any deviations from the desired dimensions and correct them before the mold is used in production.

Another aspect of dimensional control involves the heat treatment process. Heat treatment can alter the physical properties of the mold material, affecting its size and shape. By carefully controlling the temperature and duration of the heat treatment, manufacturers can minimize these changes and maintain the dimensional accuracy of the Plastic Industrial Tray Mould.

The use of precision measurement tools, such as calipers and micrometers, is also crucial during the assembly of the Plastic Industrial Tray Mould. These tools allow for the fine-tuning of the mold's components to ensure that they fit together perfectly and produce trays with the desired dimensions.

Furthermore, the maintenance and storage of Plastic Industrial Tray Moulds are critical to their dimensional integrity. Molds should be stored in a controlled environment to prevent warping or other damage that could affect their size. Regular maintenance, including cleaning and lubrication, can also help to preserve the mold's dimensions over time.

In conclusion, controlling the dimensional accuracy of Plastic Industrial Tray Moulds is a multifaceted process that involves careful design, material selection, precision manufacturing, quality control, heat treatment, and proper maintenance. By implementing these strategies, manufacturers can ensure that their Plastic Industrial Tray Moulds produce trays that meet the highest standards of size and shape, ultimately leading to customer satisfaction and a competitive edge in the market.