In the context of sustainable aquaculture practices, the energy efficiency of equipment is a critical factor to consider. Among the various tools used to maintain optimal water quality, the aquaculture paddle wheel aerator stands out as a common and effective piece of equipment. Its primary function is to increase dissolved oxygen levels and circulate water, which are essential for the health and growth of aquatic species. However, the question of how much energy these aerators consume is a significant one, as it directly impacts the operational costs and environmental footprint of aquaculture operations.

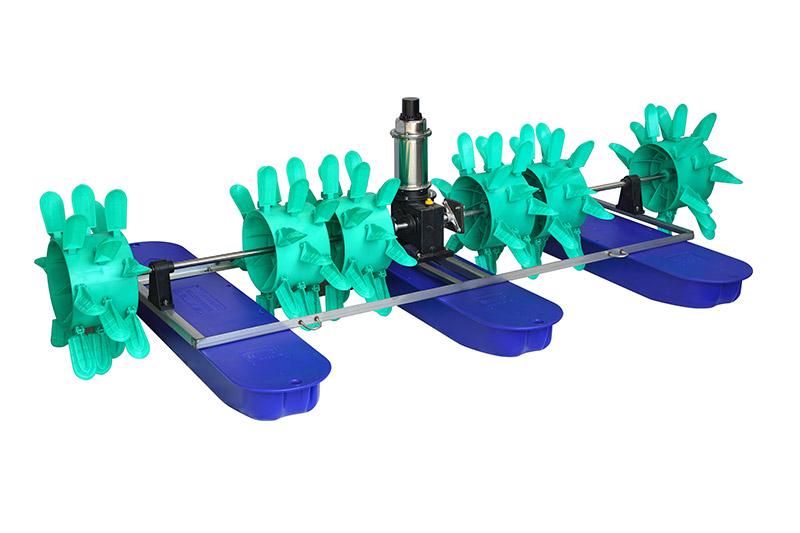

The aquaculture paddle wheel aerator operates by using a motor to rotate one or more paddles, which in turn agitate the water and create a flow. This mechanical action not only oxygenates the water but also helps to distribute nutrients and remove waste products more evenly throughout the pond or tank. The energy consumption of these aerators is influenced by several factors, including the size of the paddle wheel, the speed at which it rotates, the depth and surface area of the water body, and the power of the motor driving the system.

One of the key advantages of the aquaculture paddle wheel aerator is its relatively low energy consumption compared to other aeration methods. This is because paddle wheel aerators are designed to be highly efficient in transferring energy from the motor to the water. The energy used is primarily converted into kinetic energy, which is used to move the water and create the necessary aeration. This efficiency is further enhanced by the design of the paddles, which are often shaped in a way that maximizes the transfer of energy to the water with minimal loss.

However, the energy consumption of an aquaculture paddle wheel aerator can vary widely depending on the specific model and its settings. For instance, larger aerators with more powerful motors will naturally consume more energy than smaller ones. Additionally, the speed at which the paddles rotate can be adjusted, and this can have a significant impact on energy use. A slower rotation speed may be sufficient for maintaining adequate oxygen levels in the water, but it will consume less energy than a faster speed.

It's also important to consider the energy source for the aquaculture paddle wheel aerator. Many modern systems are designed to be compatible with solar-powered motors, which can significantly reduce the energy costs associated with operation. This is particularly beneficial in regions with abundant sunlight, as it allows for a more sustainable and cost-effective approach to aeration.

In terms of energy efficiency, the aquaculture paddle wheel aerator also benefits from its ability to be used in conjunction with other aeration methods. For example, it can be combined with diffused air systems to create a hybrid aeration approach that maximizes oxygen transfer while minimizing energy use. This flexibility allows operators to tailor their aeration strategy to the specific needs of their aquaculture system, ensuring optimal water quality while keeping energy consumption in check.

In conclusion, the energy consumption of aquaculture paddle wheel aerators is a multifaceted issue that depends on various factors, including the size and design of the aerator, the operational settings, and the energy source. While these aerators are generally considered to be energy-efficient, operators must select the appropriate model and settings for their specific needs to minimize energy use. By doing so, they can contribute to more sustainable and cost-effective aquaculture operations, which is essential for the long-term viability of the industry.