The performance of an Aluminum Profile Heatsink is a critical factor in the thermal management of electronic devices. As the temperature of the environment in which these heatsinks operate varies, so too does their efficiency in dissipating heat. Understanding how Aluminum Profile Heatsinks perform under different temperature conditions is essential for engineers and designers who aim to ensure the reliability and longevity of their products.

Aluminum Profile Heatsinks are widely used due to their high thermal conductivity, lightweight nature, and cost-effectiveness. However, their performance is not static; it is influenced by the ambient temperature and the heat load they are required to handle. In cooler environments, an Aluminum Profile Heatsink may perform exceptionally well, as the temperature difference between the heatsink and the surrounding air is greater, allowing for more efficient heat transfer.

Conversely, in high-temperature environments, the performance of an Aluminum Profile Heatsink can be compromised. When the ambient temperature is close to or exceeds the temperature of the heatsink, the rate of heat dissipation decreases. This is because the temperature gradient, which drives the heat transfer, becomes smaller. As a result, the heatsink may struggle to maintain the desired temperature for the electronic components, potentially leading to thermal throttling or even damage.

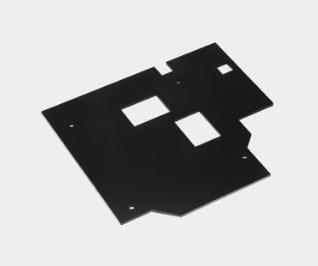

The design of the Aluminum Profile Heatsink also plays a significant role in its performance at different temperatures. Fins, for instance, increase the surface area available for heat dissipation, but their effectiveness can be reduced in high-temperature conditions due to the reduced temperature gradient. Additionally, the material properties of aluminum itself can be affected by temperature. While aluminum maintains its strength and conductivity over a wide range of temperatures, extreme heat can cause it to expand, potentially affecting the structural integrity and contact with the components it is cooling.

To mitigate these issues, engineers often employ strategies such as increasing the surface area of the Aluminum Profile Heatsink, using fans or other cooling methods to lower the ambient temperature or selecting materials with different thermal properties for high-temperature applications. These approaches help to maintain the performance of the heatsink across a broader range of temperatures.

It's also important to consider the thermal interface materials used between the Aluminum Profile Heatsink and the components it cools. These materials, such as thermal paste or pads, can degrade over time or under high temperatures, affecting the heat transfer efficiency. Regular maintenance and replacement of these materials are necessary to ensure optimal performance.

In conclusion, the performance of an Aluminum Profile Heatsink is intricately linked to the temperature conditions in which it operates. While aluminum is an excellent material for heat dissipation, its performance can be affected by both high and low temperatures. By understanding these dynamics, engineers can design systems that maintain optimal thermal management, regardless of the environmental conditions. This ensures the continued reliability and performance of electronic devices in a variety of settings, from the coldest climates to the hottest.